- Home

- Brake Type

- Material

- 100% Carbon Fibre (2)

- Alloy (37)

- Aluminium (24)

- Aluminum (74)

- Aluminum, Alloy (8)

- Aluminum, Carbon (22)

- Aluminum, Steel (5)

- Carbon (610)

- Carbon Fiber (225)

- Carbon Fiber, Carbon (9)

- Carbon Fibre (580)

- Carbon Fibre, Carbon (57)

- Carbon, Carbon Fiber (482)

- Carbon, Carbon Fibre (23)

- Chromoly (2)

- Full Carbon (10)

- Kohlefaser (8)

- Leder (2)

- Titanium (2)

- ... (722)

- Set Includes

- 2 Wheels (8)

- Axle (4)

- Bike Wheelset (6)

- Bottom Bracket, Hubs (10)

- Brake Pads (4)

- Brake Set (22)

- Brakepads (6)

- Brakepads, Skewers (15)

- Carbon Wheel Set (5)

- Cassette / Freewheel (18)

- Hubs (444)

- Hubs, Wheel Set (129)

- Road Bike Wheelset (5)

- Road Wheelset (11)

- Tires (4)

- Wheel Set (11)

- Wheels (45)

- Wheels, Wheelsets (13)

- Wheelset (74)

- Wheelsets (80)

- ... (1990)

- Tire Type

- Clincher (1234)

- Clincher / Tubeless (6)

- Clincher / Tubular (6)

- Clincher Or Tubeless (2)

- Clincher Tires (74)

- Clincher Tubeless (2)

- Clincher, Tubeless (13)

- Clincher, Tubular (3)

- Hookless (2)

- Tubeless (356)

- Tubeless Clincher (3)

- Tubeless Ready (8)

- Tubeless Tires (2)

- Tubeless, Clincher (6)

- Tubular (178)

- Tubuless (4)

- Tubuless, Clincher (4)

- ... (1001)

- Valve Type

- Wheel Size

Ultralight 1314g Road Disc Carbon Wheelset 40 45 50 65mm Ratchet For Racing Bike

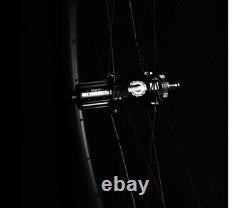

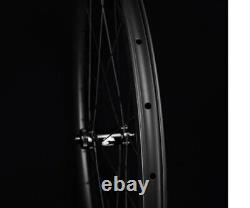

ELITEWHEELS EDGE Ultralight 1320g Road Disc Carbon Wheelset 40 45 50 65mm Ratchet System 36T HUB Wing 20 Spoke For Racing Bike. The EDGE wheelset will be the representative work of Elitewheels. The EDGE wheel set will be the most competitive competition wheel set. The ultra-light road disc brake wheel set will weigh only 1310g or less. It is the most energy-saving wheel with high-speed conductivity. The front and rear hubs are made of 7075 aluminum alloy material, the freebody is ratchet system, standard with 36 teeth, lightweight design. The front and rear hubs use Taiwan TPI bearings, front hub Quick release and 12×100 through axle compatible, rear hub Quick Release, 12×142 and 12×135 compatible. The freebody can choose Shiman0 or SRAM XDR. All EDGE wheel series are tubeless compatible, if you want to use tubeless tire, we will be equipped with tubeless rim tape. Standard use Pillar wing 20 spokes. Both front and rear wheels use 2x cross lacing hand-built wheel.

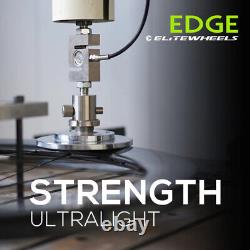

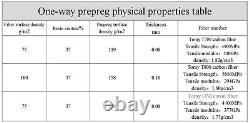

Each spoke has 16 times tension releases. The deflection of the wheel is guaranteed to be within 0.2mm. Eye-catching ELITEWHEELS valve logo and Pillar official decal. After two years of continuous experimentation on lighter carbon fiber materials and the research and development of resins by the yuan an bike team, a set of optimal material ratios was finally reached. This is between T800 and T1000 of Toray..

This is the composition table of the special materials used in T800, T1000 and. You can see its tensile strength, the tensile modulus should be more balanced. In all the test values, the strengths of EDGE are better than those of rims made of ordinary materials. All test data are from Yuan'an laboratory. Since Elitewheels was established in 2013, its objective has been to manufacture carbon fiber wheels of the highest quality. After 10 years of hard work, Elitewheels now has thousands of satisfied customers from all around the globe. As we manufacture the wheels in our own factory, we have no need to outsource production. Because of this, we have more control over production and quality control. This allows us to adapt very quickly to an ever-changing market and better provide to the needs of our customers. Our goal is to change the way you think about carbon bike wheels by delivering premium products at radically fair prices.Elitewheels has been able to expand. We have been building a global dealer and service network since early 2022. Our wheels are now competing on the world stage in World Championships as well as some of the most well known UCI races.